For more than 30 years, the Fraunhofer Institute for Laser Technology ILT has been shaping metal additive manufacturing with pioneering system and process innovations. At Formnext from November 18 to 21, 2025, in Hall 11, Stand D31, the laser institute will present its comprehensive portfolio focused on key industry challenges, lowering costs, reducing rework, and making components more robust: from high-strength tungsten components and multi-material approaches for extremely stressed parts in fusion applications, to highly productive simultaneous coating and finishing processes that save time and energy, and on to smart structures such as printed sensors that turn metal components into intelligent parts.

“Whether demonstrator or series production, the aim of developments at Fraunhofer ILT is typically to make processes faster and more robust while ensuring component quality,” explains Dr. Tim Lantzsch, Head of the Laser Powder Bed Fusion (LPBF) Department at Fraunhofer ILT.

The exhibits at Formnext 2025 illustrate this approach along the entire process chain: an aluminum-scandium distributor housing for fuel cells, an LPBF-manufactured optical carrier for satellites, a 2-kW LCoS experimental setup for freely shapeable beam profiles, and LPBF structures with adjustable porosity.

In selective laser sintering (SLS), the focus is on process development for new materials. The flexible laboratory systems at Fraunhofer ILT can already process even very small quantities of powder, such as very soft thermoplastic polyurethanes (TPU) and shape-memory polymers. The goal is to specifically tailor properties and determine robust parameters for new applications and series production.

“We think about additive manufacturing from the perspective of component function, connect material, process, and data, reduce cost per part, and increase quality and availability. We see ourselves as problem solvers and process developers from the idea stage through to stable production at the industrial partner,” Lantzsch continues.

Tungsten Components for Fusion Energy

Plasma-exposed components in fusion reactors, such as reactor wall armor, must withstand cyclical thermal loads of up to around 20 MW/m² and intense radiation. Under these extreme conditions, virtually only pure tungsten is suitable. Until now, however, the material has forced the use of simple geometries and complex joining solutions. Differences in thermal expansion cause soldered joints to fail under thermal cycling, reducing service life and system availability.

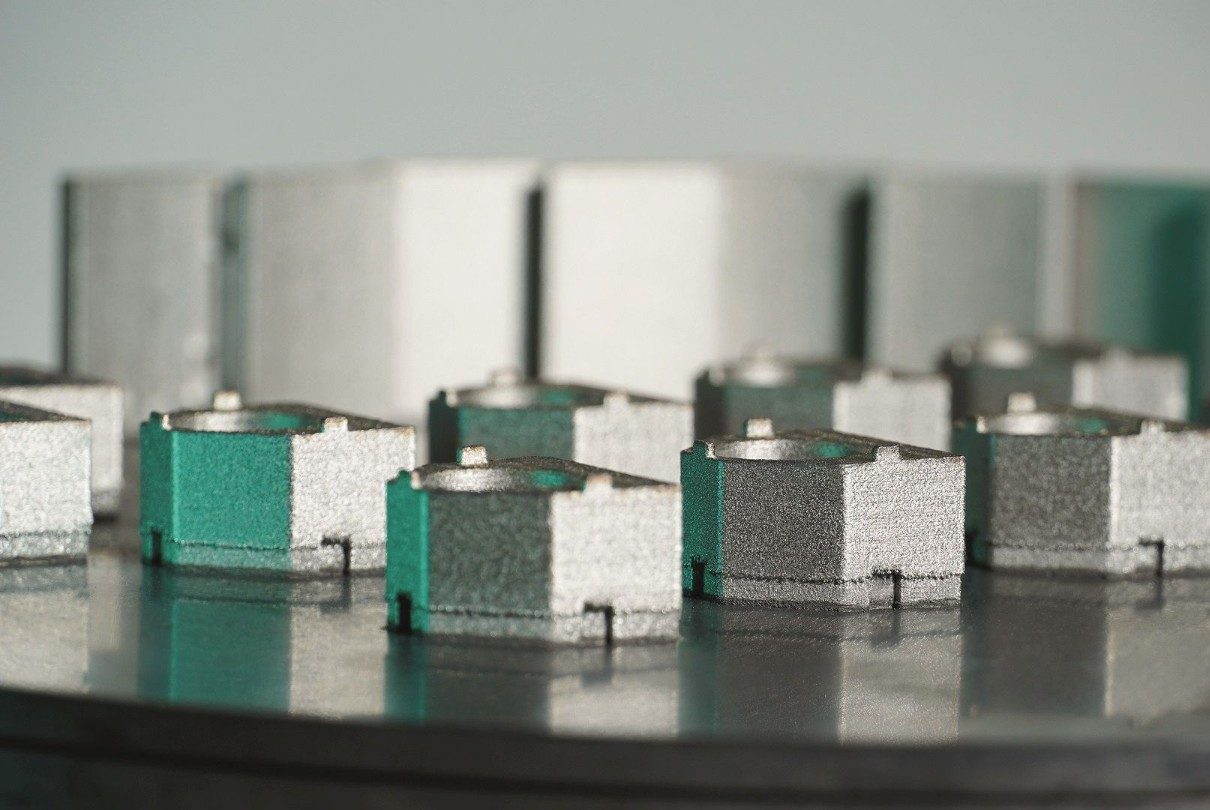

The DURABLE project addresses this precisely. Additive processes enable monolithic or multi-material components made of tungsten and copper alloy with a continuous heat path instead of critical joining zones. Process control is decisive: new system technology and parameter windows achieve nearly crack-free, high-density tungsten structures in PBF-LB/M. This allows complex geometries with conformal cooling to become possible.

“The benefit lies in longer component service life, less rework, and lower risk at joining points—a prerequisite for extending maintenance intervals and reducing costs per operating hour,” says Niklas Prätzsch, Group Leader for LPBF Process and Systems Technology at Fraunhofer ILT.

Optimizing Surfaces in a Single Step

Viktor Glushych, Group Leader for LMD Coating and Heat Treatment at Fraunhofer ILT, is pursuing a groundbreaking new approach with Extreme High-Speed Laser Metal Deposition (EHLA). The process coats quickly and resource-efficiently, but machining is usually required afterward. “Simultaneous Coating and Roller Burnishing” (SCaRB) combines EHLA with roller burnishing in a single step. While the applied layer is still warm, a rolling tool passes over the surface, plastically densifying it and smoothing roughness peaks. This creates a dense surface layer with compressive residual stress and high surface quality—without material removal or additional setup.

“This saves time, tools, and material,” Glushych explains. “At the same time, SCaRB allows targeted influence on microstructure and residual stresses. This improves wear and corrosion resistance and increases the fatigue strength of coated components.” At Formnext, Fraunhofer ILT will present an EHLA-rolling demonstrator that shows this combined process live.

PFAS-Free Multi-Material Coatings

In addition to pure metal coatings, multilayer coatings of dissimilar materials can also be applied. Here, EHLA metal coatings are combined with the application of a PEEK layer to create functional composite coatings. PEEK is a fluorine-free high-performance polymer and an attractive alternative to PFAS coatings. “The novelty lies in using the residual heat from the EHLA process to melt a deposited PEEK layer in the immediately following step,” explains Rebar Hama-Saleh Abdullah, research associate at Fraunhofer ILT. A nozzle technology developed at the institute enables homogeneous application. “This hybrid coating system combines the properties of two individually adjustable functional layers.”

The EHLA metal layer can serve as corrosion protection (for example in pistons), as an emergency running layer (for example in wind turbines), or as a heat-conducting intermediate layer. The applied PEEK layer serves, depending on added additives, as a release layer, sliding layer, or additional corrosion protection. “Adhesion between metal and polymer is achieved by mechanical interlocking of the plastic with the intentionally rough surface generated by EHLA,” explains Dr. Christian Vedder, Head of the Surface Engineering and Material Removal Department at Fraunhofer ILT.

Printed Sensors, Intelligent Components

In additive manufacturing, components are built layer by layer, making areas accessible that cannot be reached from the outside. This enables sensors to be directly integrated into metal parts, such as printed strain gauges in LPBF components. Sensor layers are produced by inkjet, aerosol-jet, or pad printing and can be applied during or after the build process with precise positioning. The resulting smart components provide real-time data on loads, deformation, or the onset of crack formation.

“These sensors are located exactly where data are most valuable—even in zones inaccessible with conventional manufacturing,” says Dr. Samuel Moritz Fink, Group Leader for Thin-Film Processes at Fraunhofer ILT. “This enables condition monitoring in operation, predictive maintenance, and greater operational safety. At the same time, system complexity is reduced because separate assemblies, cables, or external measurement points can be eliminated. Target industries range from aerospace and energy to mechanical engineering.”

Problem Solvers and Process Developers

For companies working in metal additive manufacturing, key challenges include high unit costs, complex application development, and the qualification and certification of processes for series production. This is precisely where Fraunhofer ILT’s portfolio comes in: identifying bottlenecks, developing stable processes, and rapidly transferring applications into production—from initial functional prototypes through to robust manufacturing at the customer’s site.

“New materials are the key to making the special strengths of SLS—maximum design freedom and freedom from support structures—usable in more and more industries. With our modified machines, we can efficiently qualify these materials and thus overcome the chicken-and-egg problem of industrial systems,” explains Vera Rothmund from the Application Development Group at Fraunhofer ILT.

“At Fraunhofer ILT, we see ourselves as partners to industry. We develop customized processes and technologies to solve key challenges in metal 3D printing—ranging from productivity and quality assurance to economic efficiency—together with companies,” says Dr. Thomas Schopphoven, Head of the Laser Cladding Department at Fraunhofer ILT.