Complications caused by infections after the implantation of medical devices are not uncommon. The risk increases in heavily contaminated wounds, which frequently occur especially in war zones such as Ukraine – but it is precisely there that many bone injuries need to be treated. Researchers at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Bremen have developed a novel surface functionalization that can be loaded with an antibiotic.

In view of the heavy burden on the Ukrainian healthcare system caused by a large number of poorly healing bone defects, Fraunhofer IFAM decided to provide assistance in 2023. In addition to the news situation, personal connections were decisive: “Two of our employees come from Lviv and were involved in the project from the very beginning. Through them, contact was established with the National Rehabilitation Center UNBROKEN in Ukraine, with which we are now working closely to best understand the needs on the ground and further develop the technology in a targeted manner,” says Dr. Kai Borcherding, Head of the Medical Technology and Life Sciences business unit at Fraunhofer IFAM. The MAOmed project is funded by the Fraunhofer Future Foundation.

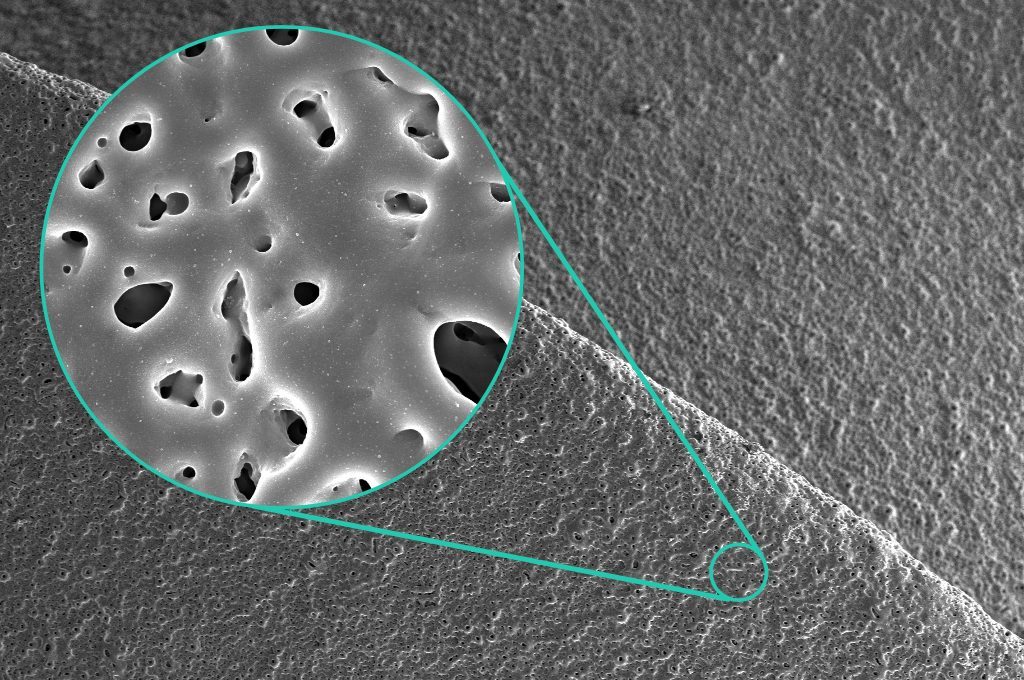

Special process creates pores on the surface

The researchers’ idea: they use so-called micro-arc oxidation (MAO) to produce a novel surface on titanium implants. The metal parts are immersed in an electrolyte – a conductive liquid – containing silver salts and are exposed to a voltage of up to 300 volts. High-energy plasma discharges create a silver-containing oxide layer on the material within minutes, in which pores are formed through controlled current flow and silver is incorporated as nanoparticles. These reservoirs can subsequently absorb antibiotics or other active substances like a sponge.

Local antibiotic delivery and silver reduce infection risk

By selecting the electrolyte and controlling the process parameters, the researchers can regulate the size and structure of the resulting pore network. This is important for the loading capacity and the duration of antibiotic release: “After completion of the MAO layer, the metal parts are immersed in an antibiotic solution at the highest possible concentration. Capillary forces uniformly fill the pores up to their defined capacity with the active substance, which is then released again in the body through diffusion. How the antibiotic is delivered over the desired period, we tested directly here at the institute through in vitro tests – after developing the surface and successfully identifying project partners,” explains Linda Gätjen, Deputy Head of the Polymer Chemistry and Materials Behavior Department at Fraunhofer IFAM. Laboratory testing also demonstrated that the integrated silver particles provide additional support to the antibiotic.

Simple and rapid coating process

This type of surface treatment is completely new in the field of implants: “There is currently nothing comparable on the market. Overall, there are only a few solutions for medical devices that work with antibiotic-containing coatings, and when they exist, the manufacturing process is much more complex,” emphasizes Kai Borcherding.

The simple setup – even under difficult conditions – is a major advantage of the method: essentially, only a power supply and a cooling unit for the immersion bath are required to carry out the MAO coating process. This makes it so easy and cost-effective to implement that in later development phases it could even be performed directly in crisis areas. Added to this is the excellent biocompatibility of the MAO surface, which ensures good and rapid integration of the implant into the body.

Further development of the technology – for Ukraine and beyond

How the new coating proves itself in practice is to be tested in Ukraine in the future. The next steps initially consist of preclinical further development of the technology and clinical studies that could be carried out at the UNBROKEN National Rehabilitation Center in Lviv. The center is the largest institution for the clinical treatment of war casualties in Ukraine: more than 10,000 operations have been performed there since the start of the war – clinical demand for safe implants is high, which is why UNBROKEN is planning long-term access to production capacities. At present, however, the team is still seeking partners in Ukraine and Europe who could further advance the project and manufacture prototypes locally.

The method is also attracting interest in Germany. The company KLS Martin, as a technology partner of Fraunhofer IFAM, has already provided sample implants with which the Bremen researchers are currently working – a first step toward application. Dr. Tobias Wolfram, Head of Implant Research at KLS Martin, explains: “In addition to the high ethical value of the project, we see great potential in the MAO method for medical technology – not only in the field of bone implants. We are therefore happy to support the team with our know-how and materials.”

Funding program “Rebuilding Ukraine – resilient and sustainable”

The Fraunhofer Future Foundation supports Ukraine in rebuilding its country through a dedicated program that enables research cooperation between both countries. Since 2024, the foundation has funded nine projects in which research teams together with companies and organizations from Germany and Ukraine are developing technological solutions for use in Ukraine. The foundation will continue its commitment with a special program in 2026 as well.