Zeltwanger Maschinenbau GmbH has specialized as a service provider in highly complex machining and serves customers from the semiconductor and automotive industries, medical technology, and micro-automation with high-quality parts and assemblies. With the CAD/CAM technologies hyperMILL MAXX Machining, hyperMILL TURNING Solutions, and hyperMILL VIRTUAL Machining, the company fully exploits the possibilities of the software from OPEN MIND and also acts as a beta tester.

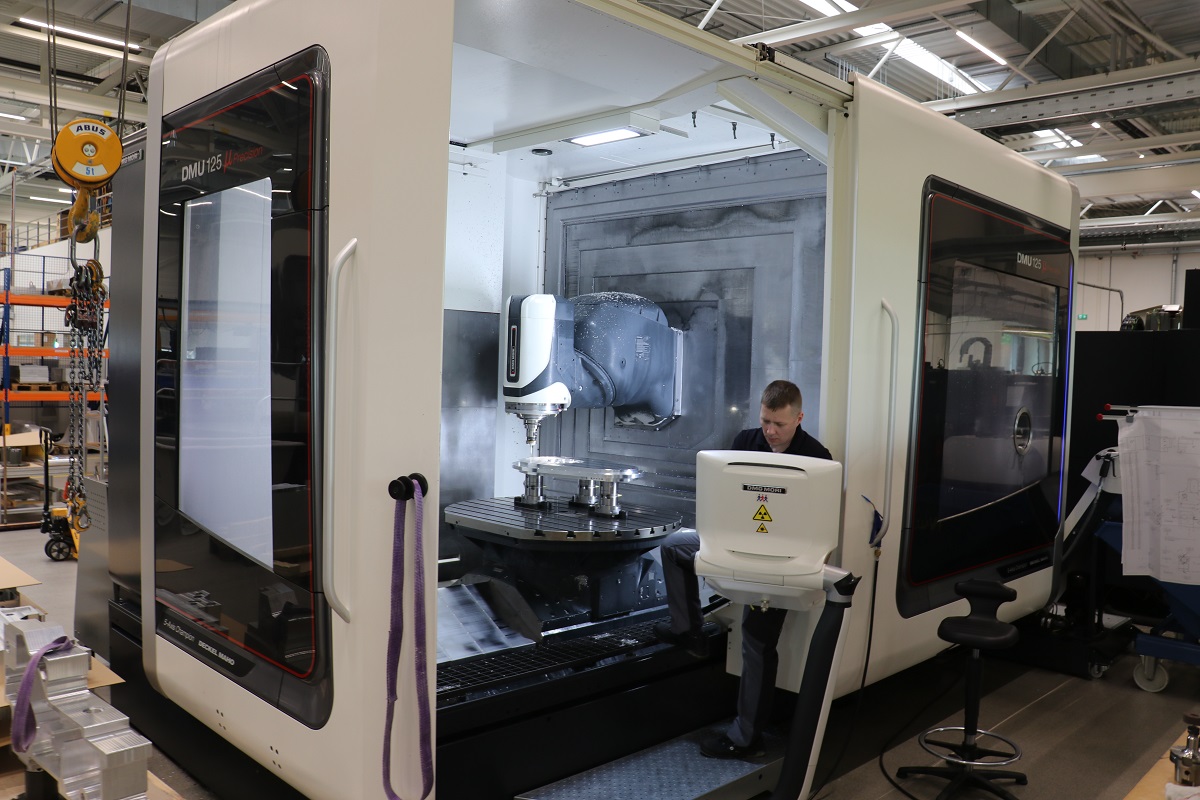

Zeltwanger’s customers are highly demanding. For a company in the semiconductor industry specializing in laser technology, the contract manufacturer supplies various components, all requiring the highest precision – ranging from pinhead-sized stainless-steel parts to workpieces weighing 250 kg, machined from aluminum blocks weighing three tons. “Micron-level tolerances are part of our everyday business,” says Wolfgang Pfeiffer, Head of CAM Programming at Zeltwanger Maschinenbau. “Since batch sizes range from single parts up to small series of around 500 units, we must generate an average of between 20 and 60 ready-to-run, safe NC programs per week, depending on complexity. To handle this workload, we program in two shifts and need CAM software that supports us simply, quickly, and with maximum process reliability.” Zeltwanger has been using hyperMILL since 2008, and the ten-member CAM programming team has expanded its capabilities with optional software modules such as the TURNING Solutions and VIRTUAL Machining.

Turn-Milling for Economical Complete Machining

Zeltwanger now also relies on turn-mill centers. Wolfgang Pfeiffer explains the advantages: “By combining turning and milling on one machine, many parts can be completely machined in a single setup. This eliminates idle times during machine changes and avoids repositioning errors.” Programming such hybrid machines involves high requirements, but with hyperMILL TURNING Solutions and the integrated TURN-MILL Machining, implementation is reliable. “The operation of the turning functions is designed largely analogous to milling, so for our experienced colleagues it was virtually self-explanatory,” Wolfgang Pfeiffer continues. Programmers thus obtain reliable toolpaths and dependable simulation for these collision-prone machines. For mill-turn centers, hyperMILL also provides ideal support with the MILL-TURN Machining module. It enables powerful milling strategies to be combined with turning operations, allowing complete machining with high efficiency, precise manufacturing results, and maximum safety.

Accuracy Secured

With hyperMILL VIRTUAL Machining, NC code can be generated, optimized, and simulated safely. This allows Zeltwanger to achieve the highest level of safety in milling, turning, and hybrid machining. Wolfgang Pfeiffer says: “Only programs that have been successfully tested – meaning safe and collision-free – are released by the software.”

Zeltwanger uses the software module intensively and now acts as a beta tester for hyperMILL VIRTUAL Machining, especially in the milling-turning area, which OPEN MIND continues to expand in terms of virtual machine utilization.

About Zeltwanger Maschinenbau GmbH

Zeltwanger Maschinenbau is part of the Zeltwanger Group, which consists of eight cooperating companies, employs more than 470 people in total, and generated revenue of €81 million in 2023. Zeltwanger Maschinenbau processes all metallic materials, primarily aluminum and stainless steel. Around 170 employees ensure that demanding customers from the semiconductor and automotive industries, medical technology, and micro-automation are supplied with components and assemblies of the highest quality.